Home » Lab Equipment Supplies » A Centrifugal Machine For Every Lab » A Centrifugal Machine For Every Lab

A Centrifugal Machine For Every Lab

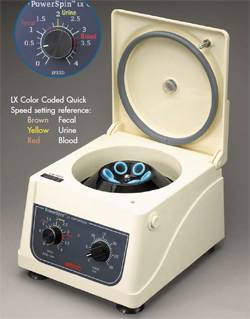

6 Place Rotor Centrifuge with Tube Holder

Retail Price: $559.87

Your Price: $447.25

Unit: single

Unit: single

6 Place Variable Speed Centrifuge Speed 4000 RPM

Retail Price: $795.64

Your Price: $579.29

Unit: single

Unit: single

Fixed Angle 6 Place Lab Centrifuge

Retail Price: $2,496.19

Your Price: $2,052.65

Unit: single

Unit: single

A centrifugal machine, also known as a centrifuge, is an important part of any hospital, health care or testing laboratory. These essential pieces of equipment are used daily to generate extremely high rotating speeds, creating a centrifugal force that forces materials of different densities to separate. Of course these materials do need to be in a suspension for the process to work, but they are perfect for separating the solids from the liquids and distinguishing between materials of different weights and densities within the suspension.

There are many different styles of centrifugal machines on the market today. Some are very small and easily sit on a corner countertop or workstation, tucked out of the way except when needed. Others are larger and hold greater numbers of test tubes, centrifuge tubes or microtubes, depending on the specific type of testing done within the laboratory facility. While the size does impact the number of tubes that can be tested at one time, typically most centrifugal machines will also have a variety of settings available from timers to the actual speed of the revolutions generated by the motor within the system. Many systems have programmable timers and speed settings, perfect for freeing up staff to multitask on different tests.

Different centrifugal machines have a variety of unique options that can help provide a greater range of uses for the equipment. Different speed settings will be a must on any machine, especially if you are going to be running a variety of tests in the lab. Systems that run with a high speed setting of 12,000 rpms to a low speed setting that can be adjusted down as far as 0 revolutions are perfect for even the most delicate procedures. Having the ability for the machine to get up to the set rpm speed very quickly is important, as is having a very fast stop option. A tachometer that reads the speed of the centrifuge is a terrific idea and one that can be invaluable in preventing a lot of guesswork.

Of course, in a busy lab, noise control and reduction is an essential component in choosing the right type of equipment. Some of the older models of centrifugal machines were very noisy and vibrated across the surfaces, requiring them to be permanently located and fixed to one spot. The new models have skid free suction type feet that keep the equipment in the correctly location at all times during storage or operation. Vibration free models are extremely quiet in even the smallest or busiest labs, definitely making it a much more pleasant work environment.

Digital programmable readouts and LCD displays make reading the test results much easier, preventing possible errors and misreading. Not only does this increase the accuracy of the tests but it also prevents the issues with having to rerun tests and complete re-spins. Adding easy cleaning features including stainless bowls around the central test tube or sample holder unit certainly ensures quick and simple management and maintenance of the equipment even under the most hectic use conditions. Systems with clear viewing ports or windows are also a bonus feature and allow technicians to monitor the centrifugal machine and contents at all times during operation.